MV1200-R Advance Plus

S/N 56DR1795

The new machine features the M700 series control with a 15-inch touchscreen for easier user interface. Mitsubishi is dedicated to constant innovation and strives to build only the highest quality machines.

The MV series features new improvements in machine construction, auto-threading, internal machine communication, power supply technology and operating costs. The MV1200-R also includes a new, non-contact Cylindrical Drive System. The machine’s improved features are sure to advance your EDM machining.

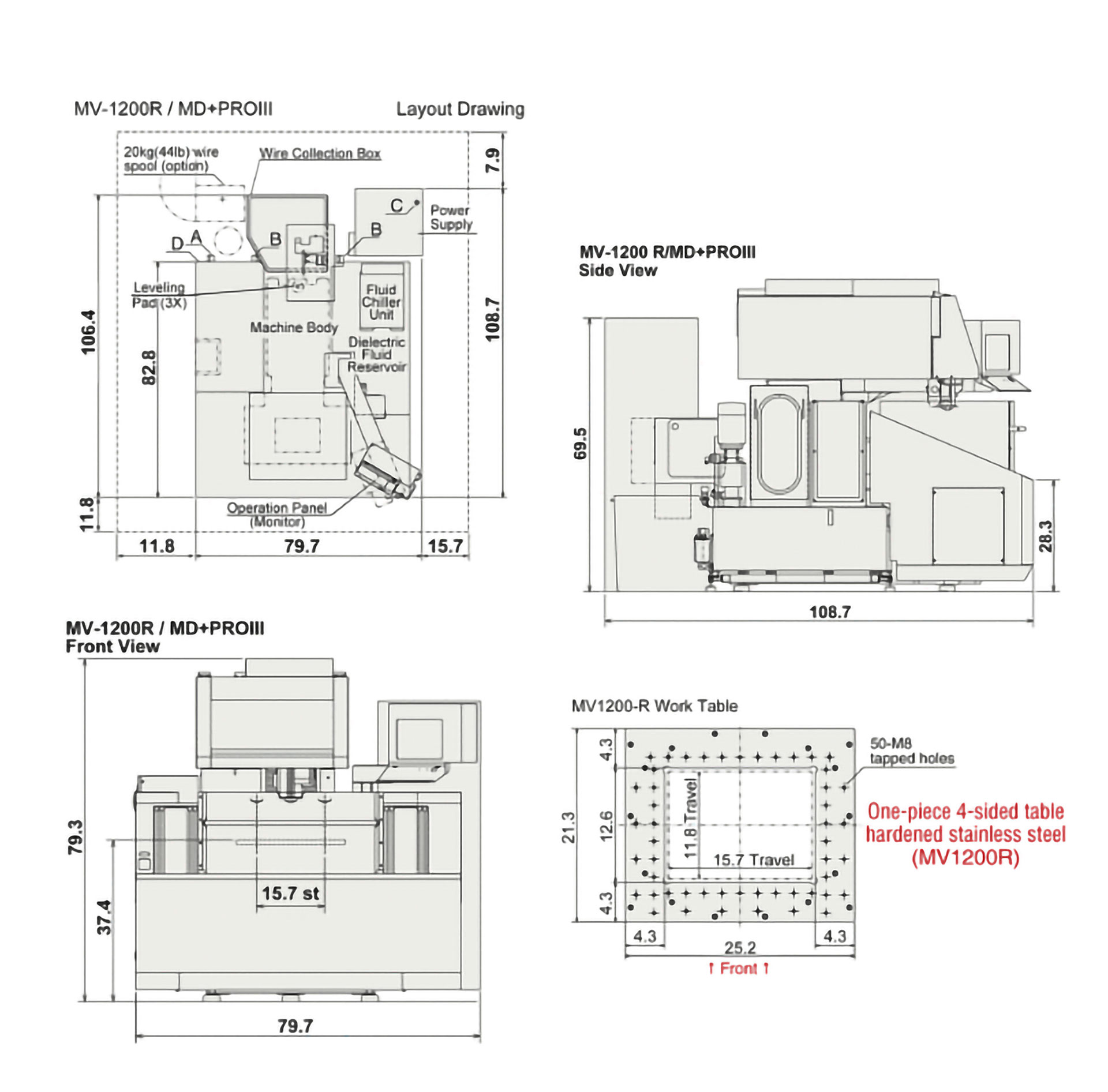

| Machine Travels: X x Y x Z in (mm) | 15.7 x 11.8 x 8.7 (400 x 300 x 220) |

| Maximum Workpiece Dimensions: W x D x H in (mm) | 31.9 x 27.6 x 8.5 (810 x 700 x 215) |

| Max. Submerged Workpiece Weight: lb (kg) | 1102 (500) |

| Table Dimensions: in (mm) | 25.2 x 21.3 (640 x 540) |

| U/V Travels (from center): in (mm) | ±2.4 x ±2.4 (±60 x ±60) |

| Taper Angle @ Thickness: in (mm) | 15 deg.@ 8.0 (15 deg.@ 200) |

| Wide Angle Taper (Optional Guides Required) | 45 deg. @ 1.8″ 45mm (No AT Possible) |

| Wide Angle Taper (Optional Guides Required) | 45 deg. @ 1.8″ 45mm (No AT Possible) |

| Table Rapid Feed Speed: in/min (mm/min) | 51.2 (1300) |

| Power Supply | V350-V |

| Minimum Drive Unit / Resolution | 0.000002 / 2 µin ( 0.00005 / 50nm) |

| User Program Storage [Hard Disk Size] | 1 GB [80 GB] |

| Wire Diameter Possible: in (mm) | 0.004~0.012 (0.1~0.3) |

| Minimum Start Hole Diameter: in (mm) | 0.02 (0.5) |

| Max. Wire Spool size STD [optional]: lb (kg) | 22 [44] (10 [20]) |

| Filters / Type | 2 / Paper |

| Filter Tank Capacity: gal (L) | 145 (550) |

| Machine System Dimensions: in (mm) | 79.7 x 106.4 (2025 x 2702) |

| Machine Installed Height: in (mm) | 79.3 (2015) |

| Machine System Weight: lb (kg) | 5952 (2700) |

| Fluid System Weight: lb (kg) | Included with machine |

| Power Requirements [KVA] | 200-230V [13.5] Built in AVR |

| Compressed Air Requirements | .7 cu.ft./min. @ 71~100 psi |

Overview

New M700 Series Control

15″ touch screen

Non-contact Cylindrical Drive Technology

Features

V350-V AEII Power Supply

DMX-S (Digital Matrix Sensor) Shapes each spark reducing electrode wear

World’s first Linear Shaft Drive System XYUV (no ball screws)

All Fiber Optic servo control (4X faster internal communication speed)

Submerged Machining to 8.7″ Deep

Automatic Fluid Level Control

Manual Vertical Machine Tank Door

One Piece Hardened 4-Sided Stainless Work Table

Fine Grain “Dianite” Casting Material

Split Axis Construction (Table Moves in X, Column Moves in Y)

Windows XP Operating System

PM5 Power Master Control Improves Poor Flush Machining up to 50%

Program Input Methods: Keyboard, USB Flash Memory, and Ethernet with FTP standard

DC-Servo (Closed Loop) Torque Control Wire Tensioning System

Non-contact, Zero Back-Lash Linear Shaft Motor Drive System (XYUV Axes)

Linear Motion Guide Ways

All-Axes Absolute Control System

Linear Glass Scale Feedback (X-Y-U-V Axes)

Optical Rotary Encoder Feedback (Z-Axis)

Auto-Threading with Scrap Wire Processor (Chopper)

New 14″ AT Annealing Length Improves Threading Reliability

Inverter Controlled 16-Step Programmable Flushing

Full Time AEII (Anti-Electrolysis) Power Supply Protection

Dielectric Fluid Chiller Standard

Full 2-yr. Warranty with Triple Diamond Partnership Program

Auto-Oiler Lubrication System